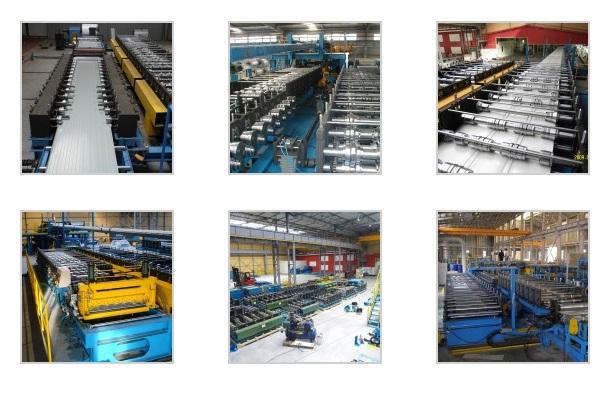

Roof tile roll forming machine

<img src="http://www.bestmadeinkorea.com/photo/2015/dn/Roof-tile-roll-forming-machine-01.jpg" alt="Roof-tile-roll-forming-machine"/>

Roof tiles, used for centuries, are greatly durable, sustainable and harmony with nature. Also, roof tiles make reduce expense, because they are easy to storage, transport and construct. That’s the reason why roof tiles are very popular all over the world.

Our roof tile roll forming machine is controlled by PLC computer system with inverter, so operators can handle the machinery easily and steadily. KINDUS, we’re keep supplying and trying for development in accordance with customer’s needs for the various kinds of roof tile.

※ Composition of equipment

Uncoiler

Entry shear

Roll forming machine

Drawing machine

Shearing machine

Run-out conveyor

Stacking

※ General specification of metal shingle roll forming machine

|

Material |

: Al/Zinc/GI/PPGI |

|

Thickness of material |

: Min. 0.3mm~Max. 0.6mm |

|

Width of material |

: Min. 914~1,390mm |

|

Production speed |

: Max. 8~13m/min |

|

Drawing depth |

: 250mm, 14~20tiles/min |

|

Drawing height |

: 15~25mm |

|

Adjustable pitch range |

: 250~400mm |

|

Drawing and cutting method |

: By hydraulic(Flying cutting) |

|

Control system |

: PLC computer control and inverter |

<img src="http://www.bestmadeinkorea.com/photo/2015/dn/Roof-tile-roll-forming-machine-08.jpg" alt="Roof-tile-roll-forming-machine"/>

Share Roof tile roll forming machine in Social Media