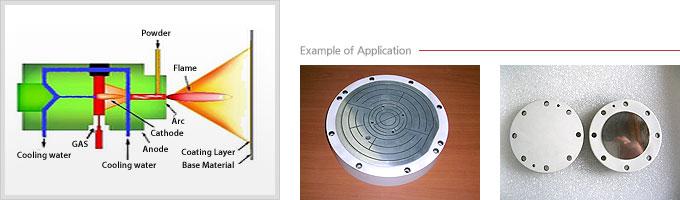

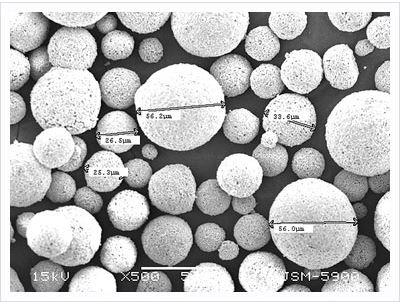

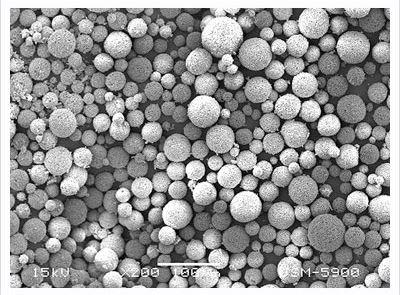

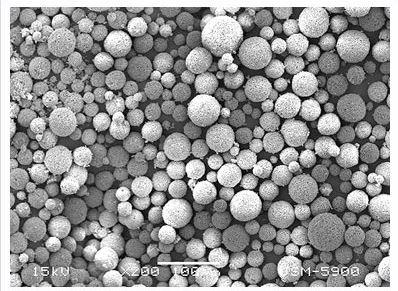

This is the coating method to form the film by injecting the film material to the plasma flow (Speed mach 2 and central temperature: 16,500��) that is generated from the inert gas by the non-transfer arc and fused momentarily to inject the completely fused powder thermal spray materials in high speed to form the films. For the thermal spray materials, there are broad selection of metals, non-metals, ceramics(mainly the oxide and carbide), and cement, and may have the outstanding films with anti-abrasion, thermal resistance, corrosion resistance, electronic conductivity, electric cover and others, and the repairing is possible with the surface temperature of the processing for thermal spray is controlled within 150�� that the coating is available for all materials.

| Material No | Ingredients(%) | Characteristics | Example of application |

|---|---|---|---|

| 101 | Al2O3-2%TiO2 -0.5%SiO2 |

Gray white color, temperature is outstanding under the high temperature of 550'C for wear resistance, corrosion resistance, acid resistance and others. | Textile machine parts, Pump seal |

| 105 | 98% Al2O3 | White color, and temperature is outstanding under the high temperature of 800'c or less for wear resistance, corrosion resistance, acid resistance and others with the electric cover | Electric insulation part, Textile machine parts, High frequency coil, Semiconductor parts |

| 130 | Al2O3-13%TiO2 | Dark blue with finite tissue, outstanding wear resistance, corrosion resistance, and acid resistance | Rewesher, Capstan, Turblne nozzle plug gaude, Textile machine parts |

| 131 | Al2O3 -40%TiO2 | Dark. blue, temperature of 550'C or below, electric conductivity | Textile machine parts, Machine parts |

| 106 | Cr2O3 -2%TiO2 | Dark gray, high hardness, temperature of 540'C or less, outstanding, acid-resistance, alkali resistance and microstructure is dense | Mechamcal seal, Textile machine parts, Wearring, Rolls |

| 204B-NS | Zr2O2- 8% Y2O3 | Corrosion prevention, thermal resistance and oxidation prevention of particle at the high temperature with the temperature of 1000'C | Rocket nozzle, Missile cap |

Share Plasma Spray Coating in Social Media