Specification

Size

1500 x 2000 x 2100 mm ( W x L x H )

Total Weight

590kg

Suitable fryer capacity(L)

1600 ~ 2400

Filtering amount (per 1 min)

100 L/min

STANDARD AMOUNT OF CELITE AND MAGNESOL

1% of total oil amount EX) 16 Kg of CELITE and MAGNESOL is necessary filtering 1600 Kg of oil.

EFFICIENCY AFTER FILTERING OIL BY THIS MACHINE

Extension of period (about twice as much as using with not filtering) of using oil with very clean condition All Sledges can be clearly removed.(up to 1 micro meter)Taste and odor of food can be much better if you use filtered oil.

CELITE is kind of diatomite which is necessary for oil filtering process as catalyst.MAGNESOL is kind of powder that is necessary for lowering FFA level.

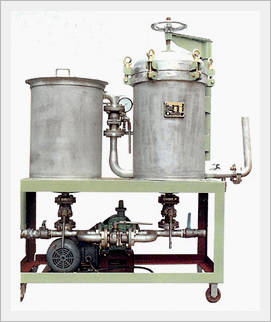

DF 18-15 AP OIL FILTERING MACHINE

DF 18-15 OIL FILTERING MACHINE is designed for 1600 ~ 2500 L size of Fryer. A filtering paper or filtering bag is not necessary. The rate of filtering by DF 18-15 AP is over 100 L/min. By Pre-coating process and simultaneous filtering method on 15 slices of filtering disk, the filtering area can be wide and the filtering rate can be fast.By MAGNESOL 3000M, which is a kinds of filtering aid, FFA level can be lowered up to 60% before filtering. DF 18-15 AP can be connected with any large size of Fryer by piping work. Also, you can use DF 18-15 separately from Fryer. Because 4 wheels are installed at the lower part of DF 18-15 AP, you can take it anywhere in your factory and execute easy filtering process.

Advantages

FFA level can be down over 60% before filtering.

Up to 1 micro meter size of particle can be removed.

Cleaning process is simple. (Just remove sludge on filtering disk.)

Because a filtering paper or bag is not necessary, you can save the expense for changing filtering paper or bag routinely.

By piping work between DF 18-15 and Fryer, the filtering process can be worked by valve control during frying work. Otherwise, you can execute the filtering process after the whole frying work is done.

The rate of filtering process is rapid. (over 100 L/min) during frying work. Otherwise, you can execute the filtering process after the whole frying work is done.

The rate of filtering process is rapid. (over 100 L/min)

Oil Filtering Machine

Description

Product Inquiry

Purchase Product Catalog

Payment & Shipping Conditions:

- Payment: We accept payment through Paypal Only.

- Shipping: We will ship the catalog once the payment is received. And you will be receiving the catalog with in 10 -14 busines days. Shipping might be delayed in due to international shipping conditions which is depends on the countries receiveing. In case hard copy of catalog is not available then we will ship the soft copy.

- Refund: We can refund the order before shipping process was initiated. Incase Catalog not available, we will make sure to refund the order.

- Note: This is a Catalog Produt.

Share Oil Filtering Machine in Social Media