| Roll forming Machines

Description

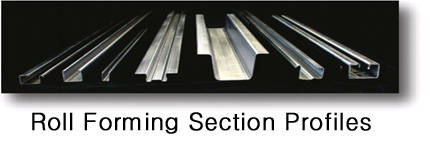

Roll forming is a continuous process that employs a series of paired roll tools to progressively shape a flat strip of metal into a desired profile. The process of progressively shaping the strip is called ‘Flowering' as gradual change in shape appears on a continuous strip as it passes through different stages of the process.

Cold roll forming holds an edge over the other production methods as it is a continuous process that eliminates stage production, finishing and sub-assembly operations. It also offers the following advantages:

Complex geometrical shapes can be produced.

Better consistency and accuracy are achieved.

Versatility in thickness and length.

Increased strength due to strain hardening.

Lightweight with rigidity saves material and cost.

Secondary operations can be combined in the continuous operation– speeds up production.

Both ferrous and non-ferrous metals can be roll formed.

Avoids secondary coating as galvanized, vinyl coated or plastic enclosed metal can be roll formed.

Increased manageability.

Maximum straightness.

Closer tolerances.

Better surface finish.

Cold roll formed products have already found their applications in various industries and are finding new applications everyday. They have replaced many conventional methods for the betterment.

Roll Forming Machines

Description

Product Inquiry

Purchase Product Catalog

Payment & Shipping Conditions:

- Payment: We accept payment through Paypal Only.

- Shipping: We will ship the catalog once the payment is received. And you will be receiving the catalog with in 10 -14 busines days. Shipping might be delayed in due to international shipping conditions which is depends on the countries receiveing. In case hard copy of catalog is not available then we will ship the soft copy.

- Refund: We can refund the order before shipping process was initiated. Incase Catalog not available, we will make sure to refund the order.

- Note: This is a Catalog Produt.

Share Roll Forming Machines in Social Media