High-quality polyurethane panel equipped with the best insulation

Using polyisocyanurate foam (PIR), which has the highest insulation quality among heat insulators, urethane panels are perfect self-assembly insulation and flame-resisting panels with superior property. These panels have better flame resistance, heat resistance and produce less smoke to maintain the advantages of PIR.

* Features of Igloo panel

High insulation quality

We use panels with excellent insulation qualities whose wall thickness is 1/2 or less of those used in construction.

Energy saving

As these panels have an insulation capacity about six times greater than concrete buildings, they have the capacity to produce warmth quickly and substantially and can reduce the amount of energy wasted.

Light and strong durability

These panels possess the virtues of being practical, strong, durable and resistant to corrosion.

Stable quality management

These panels are being manufactured under strict quality management at a factory for specialized production based on 15-years of accumulated knowledge and technologies related to urethane.

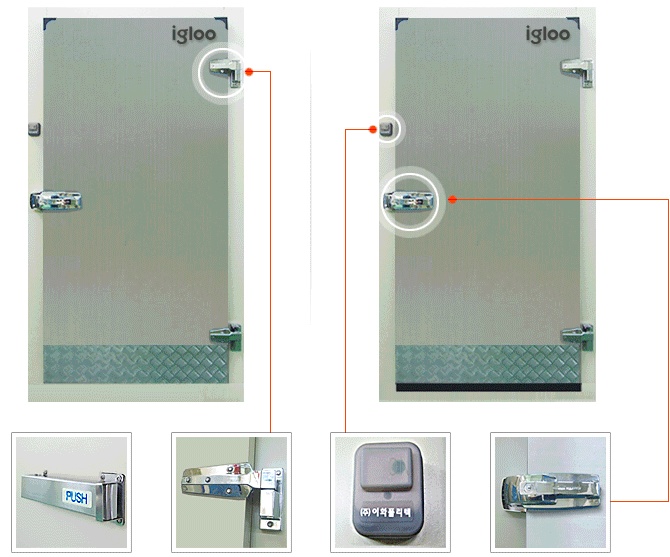

High stability

Doors have double safe escape devices for users’ safety.

Swift and accurate work

By working speedily and dealing with all aspects of the work process efficiently from orders to deliveries, the entire working period has been greatly shortened.

Easy dissemble / relocation and expansion work

By using simple structures and employing convenient working methods, processes such as disassembly, relocation and expansion are possible at any time.

Best customer service

We produce panels of three colors; ivory, vine pattern and silver, to give customers a greater choice and we try to make sure that the best follow-up and most advanced service is provided.

Light Ivory/ Vine-pattern (new product)/ Silver

Height of wall panel can be produced up to max. 7m.

Panel joints show tight insulation

Corner joints peculiar to Igloo panel

Highest-grade plastic finishes used

A kind of molding

Neat final touch

High-quality polyurethane panel with the best insulation

Leader of development of cutting-edge technology furnished with up-to-date machinery

Leehwa Polytech Co., Ltd.

High-pressure foaming machine

Up-to-date hot pressing facilities

* New product- Eco-friendly high-quality antibiotic polyurethane panel

Using polyisocyanurate foam (PIR), which has the highest insulation quality among heat insulators, urethane panels are perfect self-assembly insulation and flame-resisting panels with superior property. These panels have better flame resistance, heat resistance and produce less smoke to maintain the advantages of PIR.

* Features of Igloo panel

Used special urethane glues

The air tightness of panels has been improved using special urethane Burim for joints, instead of plastic injections.

Energy saving

The insulation quality is six times better than concrete structures and this greatly improves the warming effect and reduces energy waste.

New PVC coating steel plate

Using embossing coating steel plates with luxurious patterns, the quality of products has been upgraded.

Adopted a new assembly way

Assembling methods unique to Leehwa Polytech have been adopted and commercialized.

New assembly subsidiary materials for

A new saw-tooth-type joining material (staple) is used for the easy assembling of panel joints.

Adopted an all-in-one door

All-in-one doors are used for the easy assembling of panels, instead of a separate type.

Maintain the best insulation

Goods are produced under strict management in order to enhance the insulation capacity of panels.

Urethane Burim

Saw tooth-type panel glue

High-pressure foaming machine used

Up-to-date hot pressing facilities

Light ivory

Vine-pattern (new product)

Silver

* Materials and specifications

Classification

Specifications and properties of urethane panel

Double-sided surface material

Iron plate

0.45mm~0.8mm Colored galvanized steel

Zinc galvanizing

244~305g/m2

Surface treatment

High durable and high-heat resistant coating

Intermediate insulator

Materials

Polyurethane Foam (PIR), Polyisocyanurate Form (PIR)

Density

42 ± / 6kg/m3

Fire resistance

Self-extinguishing (Flame-retardance)

Conductivity

0.020Kcal/ mhr?

Moisture absorption

0.3g / 100cm2

Temperature

-20 ~ 90 ? (Based on 100T panel)

Gluing

Self-adhesive

Self-adhesive

Intensity

Compressive strength

30N /100 cm2

Bending strength

55N /100 cm2

Standard

Thickness

50T, 75T, 100T, 125T, 150T

Effective breadth

1000mm

Length

available to transport

* Proper temperature and application according to thickness of panel

Thickness

Proper temperature range

Application

50mm

0 ? ~ ± 15 ?

For refrigeration and low temperature

75mm

-10 ? ~ ± 15 ?

For refrigeration and low temperature

100mm

-20 ? ~ -10 ?

For refrigeration and freezing

125mm

-30 ? ~ -20 ?

For freezing

150mm

-40 ? ~ -30 ?

For freezing, quick freezing, ultra low temperature

* Soundproof of panel

Thickness

Density (g/ cm2)

Conductivity (Kcal / m2h?)

Hard urethane foam

0.035

0.015(0.018)

Styrofoam

0.03

0.032

Glass wool

0.02

0.033

Rock

0.33

0.053

Carbonized cork

0.12

0.033

Foaming concrete

0.70

0.150

Wood

0.50

0.150

* In relation to the heat conductivity of urethane foam, changes brought on by age must be considered and the formula 0.018Kcal/m2h? should be employed for calculation purposes.

Leader of development of cutting-edge technology furnished with up-to-date machinery

Share Urethane panel for refrigeration in Social Media