Advantages

High deposition rate

Wide choice of deposition sources

Better physical properties

Simple process sequence

Scalable to 300 mm wafer process

Applications

Capping layer: Al2O3

Capacitor dielectric: Ta2O5

Ferroelectric material: SBT, PZT

Electrode or barrier: Ti/TiN

Atomic layer deposition (ALD) is promising technology to deposit very thin films required for semiconductor devices such as gate dielectric and diffusion barriers. Alternate supply of reactants allows completely conformal film growth and precise control of film thickness. Slow film growth is regarded the main drawback of ALD thus efforts were focused to increase deposition rate by reducing reactant-supply time. However, there are other potential problems to be solved:

The chemical reaction between the reactants may not be facile enough. The reactant-supply time may need to be too long to be practical. If some of the reactants are not thermally stable, especially for metal-organic precursors, it is not possible to increase process temperature to promote the reaction.

The quality of the deposited films may not be good enough for the application. It may require post-process treatment, which increases manufacturing cost

Genitech developed plasma enhanced ALD (PEALD) process and equipment to solve these problems. Plasma-activated oxygen gas is used as one reactant and successfully deposit uniform Al2O3 and Ta2O5 films. PEALD of Al2O3 and Ta2O5 gives following benefits:

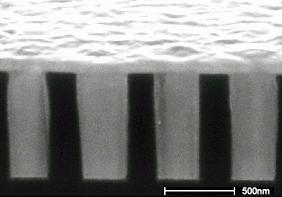

Film growth per cycle is increased by 1.5-2 times. It is 1.5 ?cycle for Al2O3 and 1.0 cycle for Ta2O5 .

No explicit purge is needed, thus reactant-supply cycle is greatly simplified and shortened. The cycle time can be as short as 1s for Al2O3 , which consists of 0.2s for trimethylaluminum supply, 0.2s for O2 supply, and 0.6s for O2 supply with plasma.

Films contain little impurities and film qualities are improved. The leakage current of as-deposited Ta2O5 film by PEALD is much less than that of the Ta-based dielectric by MOCVD. Also the dielectric constant of as-deposited Ta2O5 film by PEALD is larger than than that of the Ta-based dielectric by MOCVD.

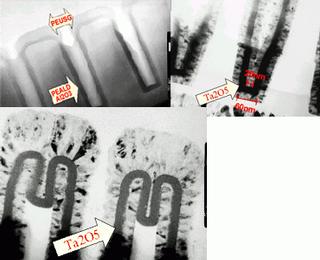

Figure 1. PEALD Al2O3 films shows perfect step coverage.

The first and second benefits greatly increase the film growth rate per unit time over conventional ALD which have to spend time for explicit purge to keep reactants from meeting in gas phase. This increased growth rate and high film quality enable PEALD competitive with conventional CVD requiring post-process treatment.

Figure 2. TEM images of PEALD Ta2O5 film on top and bottom part of storage nodes shows perfect step coverage.

Peald

Description

Product Inquiry

Purchase Product Catalog

Payment & Shipping Conditions:

- Payment: We accept payment through Paypal Only.

- Shipping: We will ship the catalog once the payment is received. And you will be receiving the catalog with in 10 -14 busines days. Shipping might be delayed in due to international shipping conditions which is depends on the countries receiveing. In case hard copy of catalog is not available then we will ship the soft copy.

- Refund: We can refund the order before shipping process was initiated. Incase Catalog not available, we will make sure to refund the order.

- Note: This is a Catalog Produt.

Share Peald in Social Media