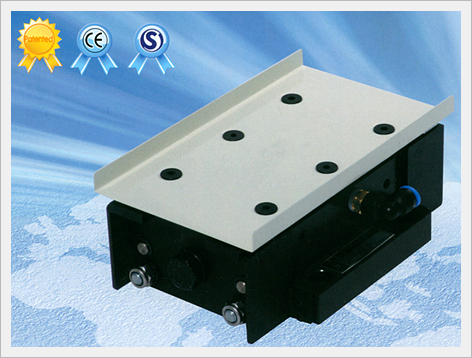

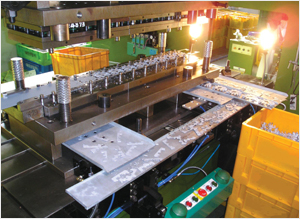

Item selecting and conveyanceThe first developed in Asia, and has the best quality and performance among existing competitive products.

Features & Advantages

Less mechanical drive noise

Simple structure and easy installation

Provide smooth transfer feed by the air intake and release of the spool valve

Possible to convey to tilt angle of Max. 8degrees depending on the weight and friction coefficient because it uses the law of inertia.

Possible to utilize for the multiple works(press, injection, selection, conveyance)

Easy to re-installation when operation is changed due to its tray structure.

Possible to effective using for the narrow gap(Min. 15mm) or deep and wide area with its tray structure.

Multiple trays can be installed with one machine.

Convenient management and maintenance due to its simple combination of compressed air and simple components.

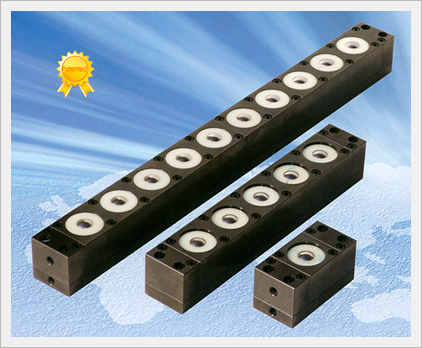

Kinds of Model

Model

SM12

SM48

SM100

Specification

Air Pressure 4.5~5.5kg/cm2)

Conveyance capacity(kg)

12

48

100

Air consumption(l/min)

12

46

130

Noise(db-A)

68

68

69

Maximum stroke length(mm)

24

26

27

Maximum tray weight(kg)

2.9

5.8

20

Recommended strokes per minute(spm)

120

110

100

Machine weight(kg)

2.5

6.5

18.2

Dimension

A(mm)

200

240

290

B(mm)

125

170

300

C(mm)

46

78

102

D(mm)

90

100

140

E(mm)

105

145

270

F(mm)

120

140

180

G(PT)

40

50

55

H(mm)

15

20

20

I(mm)

16

26

35

J(mm)

30

52

67

K(mm)

58

85

200

L(mm)

60

70

90

M(mm)

60

70

90

N

M8

M10

M10

O

M6

M8

M8

P

1/4"

3/8"

3/8"

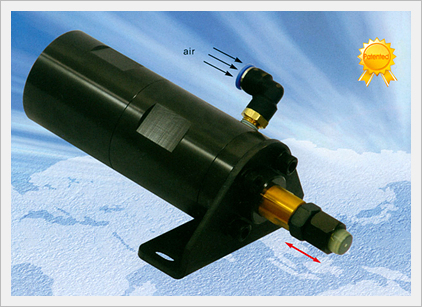

Installation & How to use

Arrangement: main air line ? drain ? 3 point combincation(air unut) ? Air conveyer/Install the ON/OFF valve at a safe area.

Pneumatic oil: Turbine oil(class#1), ISO VG32 or equivalent About 1drop per minute

Air pressure range: 4~6kg/cm2, Recommended air pressure : 5kg/cm2

Efficient release may be interrupted if the maximum tray weight is exceeded.

The upper bolt surface shall be lower than the tray surface when assembling the tray with bolts.Tray mounting Bolt : CS M6 & M8-6ea

When the tray is long and wide, bearing or a material with low friction shall be used to reinforce the lower part of the tray in order to ensure efficient horizontal movement.

The contact surface area shall be minimized when using excess punching oil because the adhesion force between the top surface of the tray and the material increases due to air tightness.

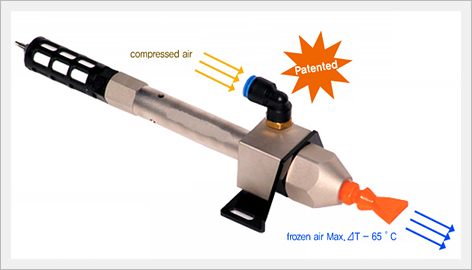

Optimum release can be achieved by controlling air pressure using speed controller and air pressure controller installed at the side of the Air Conveyer. SPM: 120~80SPM

Impurities shall be removed at least once a month from the noise suppressor installed at the lower part of the Air Conveyer.

If the Air Conveyer does not move, smoothly push the tray for efficient operation.

Transport speed: 8~10m/min

Maximum tray installation inclination(upward): 8°

Apply recommended SPM. Higher SPM can be cause of damage to the O-ring in the Air Conveyer.

Air Conveyer

Description

Product Inquiry

Purchase Product Catalog

Payment & Shipping Conditions:

- Payment: We accept payment through Paypal Only.

- Shipping: We will ship the catalog once the payment is received. And you will be receiving the catalog with in 10 -14 busines days. Shipping might be delayed in due to international shipping conditions which is depends on the countries receiveing. In case hard copy of catalog is not available then we will ship the soft copy.

- Refund: We can refund the order before shipping process was initiated. Incase Catalog not available, we will make sure to refund the order.

- Note: This is a Catalog Produt.

Share Air Conveyer in Social Media