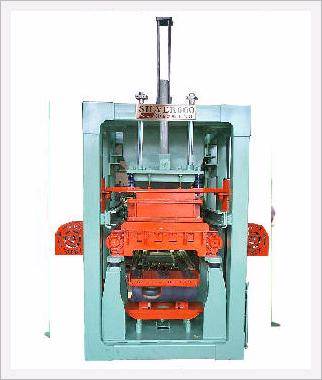

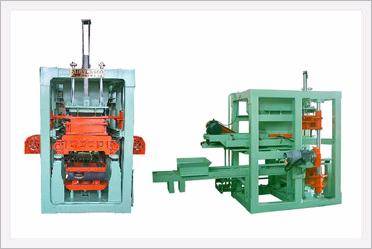

Block Machine Gold-2010/Gold-700

Models

SILVER-530

SILVER-660

SILVER-850

SILVER-900

GOLD-700

GOLD-2010

Pallet size (mm)

530 x 530 x 6

660 x 530 x 9

850 x 530 x 9

900 x 900 x 12

1,400 x 700 x 14

1,400 x 1,300 x 16

Effective area (mm)

500 x 500

630 x 500

820 x 500

860 x 860

1,250 x 650

1,300 x 1,250

Product height (mm)

60-200

60-200

60-200

60-200

60-200

60-200

Vibrator (no.)

2

2

2

2

4

4

Motors for vibration

7.5 kW x 2

22 kW x 2

15 kW x 2

18.5 kW x 2

30 kW x 2

45 kW x 2

Production capacities

Per pallet

Output per hour

Output per hour

Output per hour

Output per hour

Output per hour

Output per hour

Block 390 x 190 x 100 mm (4")400 x 200 x 100 mm

4

960-1,20

5

1,200-1,500

7

1,680-2,100

14

3,360-4,200

10

2,100-2,400

33

6,930-7,920

Block 390 x 190 x 150 mm (6")400 x 200 x 150 mm

3

810-900

4

1,080-1,200

5

1,350-1,500

10

2,700-3,000

7

1,470-1,680

21

4,410-5,040

Block 390 x 190 x 190 mm (8")400 x 200 x 200 mm

2

600

3

900

4

1,200

8

2,700-3,000

6

1,260-1,440

18

3,780-4,320

Paver UNI 225 x 112.5 x 60 mmWithout face mixWith frace mix

88

1,920-2,1601,440-1,680

1010

2,400-2,7001,800-2,100

1212

2,880-3,2402,160-2,520

1818

4,320-4,8603,240-3,780

2525

6,000-6,7504,500

5050

12,0007,500-9,000

Paver Rect. 200 x 100 x 60 mmWithout face mixWith face mix

88

1,920-2,1601,440-1,680,

1212

2,880-3,2402,160-2,520

1414

3,360-3,7802,520-2,940

2828

6,720-7,5605,040-5,880

3333

7,920-8,9105,940

6060

14,4009,000-10,800

Curbstone A(1) with face mix

3

270

5

450

Curbstone B(2)with face mix

2

180

4

360

Curbstone C(3)with face mix

2

180

4

360

Curbstone SA(4)wo/w face mix

4

720/480

7

1,260/840

Curbstone SB(5)wo/w face mix

3

540/360

6

1,080/720

Curbstone SC(6)wo/w face mix

3

540/360

6

1,80/720

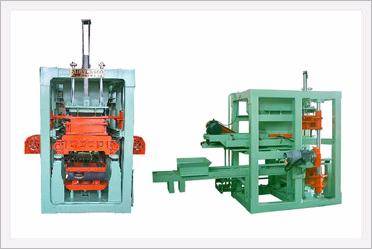

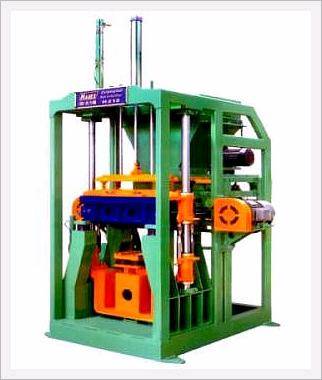

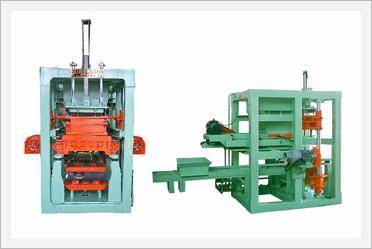

The GOLD model machines are stationary, universal concrete block machines for large-scale production of light-weight and dense concrete products: bricks, hollow and solid blocks, pavers with/without face mix layer, curbstones, retaining wall blocks, and other blocks for construction, landscaping, civil engineering and environmental protection

Heavy-duty machine frame structure with three parts: forming (press) part, base mix filling part and face mix filling part

Base mix part and face mix part can be attached to and detached from forming part for easy mould change and maintenance.

Face mix part for double layer concrete units (e.g., pavers, curbstones)is optional and can be retrofitted.

Complete block making plant with equipment for batching and mixing, block forming, transport (elevator and lowerator, finger car, etc.) and cubing

Four main shaft and sliders

Proportional control valve that can control hydraulic speed via control touch-screen

Filling box is freely suspended, so vibration is not transmitted to filling box.

Hydraulic/electrical device for lifting/lowering filling box

Agitators to facilitate filling of material into mould

Integrated vibration table with four vibrators driven by high-efficiency inverter motors (servo motors optional)

Centrifugal force of vibrators can be easily adjustable, and rpm can be infinitely variable.

Mould mounting by pneumatic air-bag clamping system allows quick mould change.

Oil heater, oil cooler, oil tank ventilator, oil temperature indicator, oil level indicator, oil filter

Control with touch screen for easy menu selection, data input and modification

For Convenience Sake

Various equipment, standard or optional, to enhance and facilitate block production

Pallet supplier/withdrawer (option)

Air spray

Device for handling defective blocks

Pallet scraper and pallet turnover

Moulds

Moulds of high precision and long life

High precision: Design by CAD, CNC-machining, and strict quality control ensure precise dimensions of moulds.

Long life: High-quality material and strict heat-treatment ensure long mould life.

Various moulds for standard or custom-designed blocks

Concrete Block Machines GOLD-2010/700

Description

Product Inquiry

Purchase Product Catalog

Payment & Shipping Conditions:

- Payment: We accept payment through Paypal Only.

- Shipping: We will ship the catalog once the payment is received. And you will be receiving the catalog with in 10 -14 busines days. Shipping might be delayed in due to international shipping conditions which is depends on the countries receiveing. In case hard copy of catalog is not available then we will ship the soft copy.

- Refund: We can refund the order before shipping process was initiated. Incase Catalog not available, we will make sure to refund the order.

- Note: This is a Catalog Produt.

Share Concrete Block Machines GOLD-2010/700 in Social Media